By GMM Technologies | 2024-11-26 | Ship Building News |

The event of Union Maritime Company (UK) ordering two 115,000DWT tankers LNG (liquefied petroleum gas) dual fuel has opened a new direction for HD Hyundai Vietnam Shipbuilding Company Limited (HD Hyundai Vietnam). This is the period when the company will launch the first ships using green, environmentally friendly energy in Vietnam.

The world’s maritime industry is racing to reduce greenhouse gas emissions as ships running on environmentally friendly fuel are constantly being researched and released. This is the direction for the shipbuilding industry in the near future. With this inevitable trend, HD Hyundai Vietnam – a subsidiary of HD Hyundai Mipo Company (under the management of Chairman Kim Hyeong-kwan), a shipbuilding company under HD Hyundai Group will officially start embark on a new generation environmentally friendly shipbuilding project using wind energy. Thereby, once again affirming HD Hyundai Mipo’s leading position in the shipbuilding field.

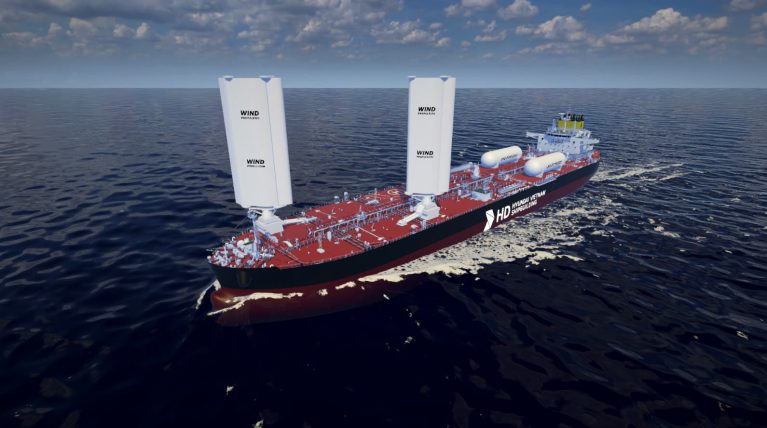

HD Hyundai Vietnam and Union Maritime Company have reached a final agreement on signing a contract to build 2 tankers with a tonnage of 115,000DWT (equivalent to 115,000 tons) running on dual fuel LNG and each ship will be installed Install 2 more Windwings sail-shaped devices to help take advantage of wind energy. It is expected that the design of these two ships will take 2 years. The first one will start construction in August 2026 and be handed over in November 2027, the second one will start construction in November 2026 and be completed in handover in April 2028.

Equipped with LNG dual fuel engines, which can use both LNG and diesel as fuel, ships newly built by HD Hyundai Vietnam will become environmentally friendly ships. Ships significantly reduce engine emissions also help increase efficiency during operation. In addition, the ship is also equipped with many environmentally friendly solutions to increase the efficiency of propulsion engines such as: Hi-PSD (Pre-Swirl Duct), a fuel-saving device exclusively invented by HD Hyundai and Hi -FIN, a device that helps balance the vortex generated from the propeller …

In particular, these ships are designed with 2 additional Windwings (sail-shaped devices) made of steel and other synthetic materials with a height of 37.5m; 20m width manufactured by UK-based BAR Technologies installed asymmetrically towards each other at the bow. The Windwings device not only adjusts to the direction of the wind, but can also be folded or lowered in crosswinds. This feature will help significantly reduce the amount of fuel used by the ship during operation. According to BAR Technologies, on an average route, each Windwings sail saves about 1.5 tons of fuel per day, equivalent to an effective reduction of 6 tons of CO2.

In 2024, HD Hyundai Vietnam has received orders for a total of 29 ships (worth 1.62 billion USD), reaching three times the target of 10 ships per year (worth 520 million USD), bringing the total cumulative orders to 56 ships, ensuring the company’s workload for the next 3 years. To achieve the 2024 revenue target of 608.1 million USD and hand over 15 ships, in 2022 HD Hyundai Vietnam invested in installing a 700-ton Goliath crane. In addition, to aim for the plan to build 20 ships/year by 2025, the company is re-establishing the entire factory system, ensuring this goal through continued expansion of infrastructure and improve production capacity.